Digitizing the shipping industry

At a glance

When a 70-year-old Japanese manufacturing company wanted to disrupt its business model – and the entire shipping industry – they called on Slalom Build.

Impact

We not only helped them modernize their organization, we helped them lay the foundation for autonomous sea vessels of the future.

Key Technologies / Platforms

- Microsoft Azure Stack Edge

- Unity Game Engine

- Computer Vision

- IoT Edge

- Azure Cloud

Industry

Manufacturing

Key Services

Japan has a problem. Two, actually. Because it’s surrounded by water, Japan’s economy relies heavily upon fishing, shipping, and other watery trades. Its lanes are plied by not only the massive shipping and ferry vessels, but also the smaller “Mom and Pop” fishing boats. The seas surrounding the more than 6,000 islands that make up the nation are as chaotic and crowded as they are utterly essential to the economy.

Second is their waning workforce. Younger generations are less-than-enthusiastic about a life at sea. Captains must be always on, which can result in crushing stress levels and early career burnout. When so many other modern options are available to them, working on a huge ship for weeks at a time is losing its appeal.

Grabbing the wheel

One very daring company decided to approach these challenges in new and transformative ways – and they called on Slalom Build to help. Help in transforming their business to digital, help in shifting the very DNA of their company from hardware to software.

Just Right Customer Solution (JRCS) is a 70-year-old, family-owned marine hardware systems integrator. They’re hardware specialists, manufacturing control panels and engine monitoring systems for vessels, but were looking to push the boundaries of what they could bring to the shipping industry – especially when it comes to safety and efficiency. So, they peered over the bow, past the hardware and instead thought far, far into the future.

What they came to understand was that future would likely involve manned – and eventually even unmanned – autonomous cargo and ferry ships. The shrinking shipping workforce combined with the need to carefully navigate between buoys, boats, and fishing nets makes eliminating – or in the short term, assisting – the human element an attractive proposition.

But shifting from hardware manufacturing to pioneering unmanned vessels was to be the biggest change in the company’s history, and they needed partners to make it happen.

To deliver the machine learning aspect of the autonomous vessels, JRCS decided that involving Microsoft was a smart first step. They also traveled to the U.S. and toured autonomous vehicle manufacturers, meeting with Tesla, Apple, among others.

The Slalom Build team was invited to conduct an agile workshop as a precursor to our Accelerate to Build (A2B) process. We deployed a team to Shimonoseki, Japan and delivered a workshop to the newly formed JRCS Digital Innovation Lab engineering team and their CEO, Koichiro Kondo. It turned out to be a dramatic first step for a hardware manufacturing company developing simple software in a waterfall industry.

Because they had an idea – but not yet a path toward a product – we followed that with a 12-week Discovery process, learning and understanding their goals and long-term strategy, and created a roadmap for the project. Together we determined what an MVP (minimum viable product) would look like, as well as defined the overall vision. By the end, the JRCS team had a product roadmap, architecture and services design, a feature backlog, and other crucial tools designed to set everyone up for success.

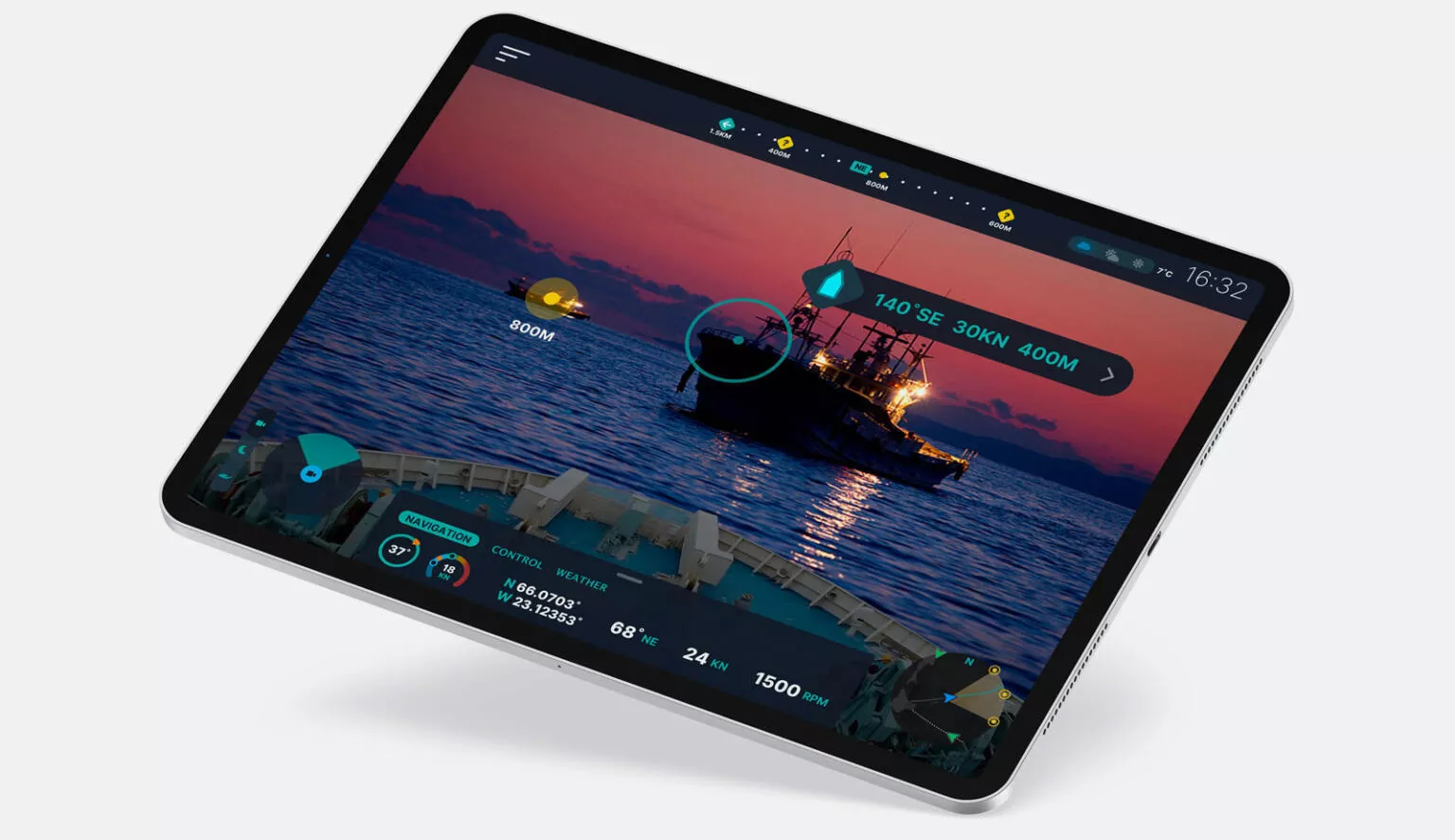

Most importantly, we came away with the single, focused goal of creating a state-of-the-art device that leverages cutting-edge technology including Microsoft edge computing, computer vision, and machine learning to drive decision support. It was to be a system to ingest live camera feeds in order to more effectively navigate the ship's course – all controlled on a handheld tablet. And we were doing it on an accelerated schedule, driving toward a robust proof-of-concept to make a splash at the upcoming SeaJapan conference.

Tides, Tech, Teams

Because they were endeavoring to completely overhaul their organization and become a modern software company, it was critical to bring the JRCS and Build teams together, in the same brainstorming room, refining the vision and immersing themselves in the agile process. The idea is that while we were helping them transform their technology skills – and the industry overall – we would also help them transform from a waterfall to agile process. A JRCS team decamped for an extended stay with their builder counterparts in Seattle.

Then, as we all know, COVID hit. SeaJapan was cancelled as Japan was one of the first countries to shut down and naturally, there was a concern for our friends getting stuck thousands of miles from their families. So their team returned home, and we carried on with a front-end proof-of-concept team, adding machine learning expertise, engineers, QE, architecture, DevOps and even an Azure cloud specialist.

But it didn’t stop there, Build supplied a truly global team across five different time zones. Take Tokyo. Slalom wasn't even a branded name there. And yet, with only a new tiny office of four people, we are helping to make enormous waves (pun maybe intended) in JRCS and the shipping industry as a whole.

When it came to tech, Microsoft Azure Stack Edge server was the natural choice. This new offering (it has just been released) enables the power of Azure’s cloud services in remote application such as aboard an ocean-going vessel. In other words, this project had JRCS and Slalom Build working on the bleeding edge as testers of Microsoft’s vision for the future of cloud.

For the interface, we needed a handheld device that could be easily carried around on ship. Something the team could easily carry and monitor anywhere. And that all spelled iPad. (Plus, it’s still considered a hot product in Japan and JRCS was looking to make the biggest splash and impression they could.) Lastly, the entire experience is being built on the Unity gaming engine, largely due to the flexibility and portability of its codebase and potential to expand capability to other devices like large screen displays, or even HoloLens. But it was a decision made with the future in mind, as Japan has a wealth of talent in the gaming industry.

All this teaming and tech has created an amazingly effective prototype to put decision support in the hands of ship captains using Computer Vision. Currently, live streaming video from the ship feeds into the Microsoft Edge device. That video is then served into to the iPad – all while feeding the machine learning engine in the background with the IOT Edge.

This video data is pulled from an array of three cameras on the ship: straight ahead, half left, half right. These views are all married together to get a full, complete picture of what's in front of the boat. The next steps are the integration of existing sensor data to not only pick up objects on the horizon, but to help determine what a given object might be: boat, buoy, bird, something else? This is truly the definition of disruptive, innovative work.

A Stellar Start

Though the industry seems light years (or at least just plain years) from fully automated vessels, this project is already a success. Build was able to form an early vision of autonomy and create a decision support product that was delivered in a scant nine months to their first customer. And in turn, JRCS delivered a workable solution faster than anyone else in the industry, showcasing themselves as innovators in the machine learning space. Plus, in the same timeline, they transformed from a waterfall based, machinery manufacturing organization into an agile software company allowing for continuous innovation at velocity and scale.

The JRCS team grew from 5 engineers to 19 while working with Slalom Build.

And from a technical standpoint this exciting project allowed our Builders to try things that have never been done. As one said, “This project is both difficult and exciting. It’s what I think about over dinner and what I wake up thinking about each day. It is what I will think back to as a highlight of my career.”

This project is proof.

Proof that international teams, often small ones, can work together to make massive impacts on ancient industries. Proof that old school hardware companies can transform themselves from the ground up and help usher their industry into the future. Proof that when daring visions meet smart processes and talented teams – extraordinary transformations can happen.