Manufacturers, make customers the center of your universe

Manufacturers win when they bake customer obsession into the product development process from beginning to end. This obsession must go beyond any single process, and be baked into an end-to-end ecosystem connecting employees, partners, processes, machines, data, and customers. Plugging into the best technology is only part of the story.

Here’s how to get there

In my 20+ years with manufacturing and automotive clients, I’ve seen a fundamental shift in the industry. Ten years ago, the customer relationship was owned by partners. The focus for manufacturers was on building products. Today, the customer experience (CX) is just as important as the products you create, and needs to be built into how you do business from top to bottom.

As manufacturers look to adapt to the changing landscape, they need to focus on improving business operations to drive a better customer experience—keeping that experience at the center, from product development to after-service support with value-add services. An estimated 86 percent of buyers will pay more for a better customer experience and greater transparency.

What does “customer experience” really mean for a manufacturer? Traditionally, many companies are organized by function, making it easy for them to perceive great customer experience as something off to the side, in a silo. But employees and teams in siloes can’t see the full picture from the customer perspective. Shifting the focus from siloes to customer journeys make it possible for manufacturers to spot and address customer pain points.

Key obstacles include:

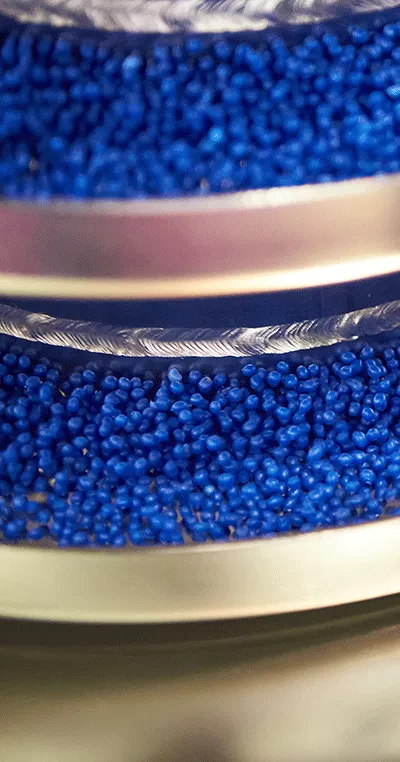

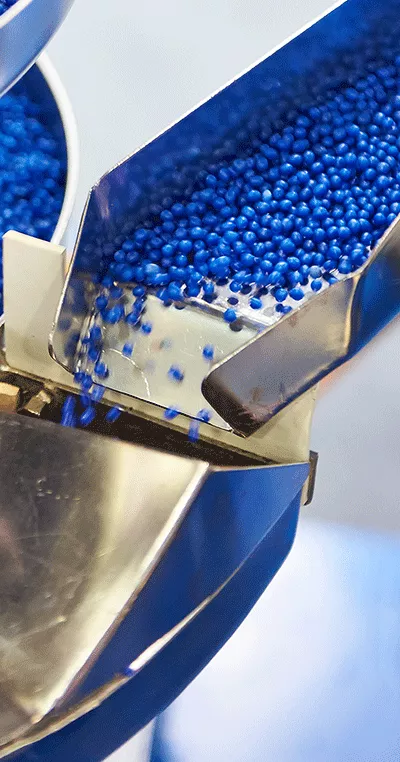

Manufacturers are modernizing their business processes and digitally transforming to solve these problems. This trend was already strong, and COVID is driving up the need for a better online experience even more urgently. Manufacturers are striving to better understand their customers and streamline their operations across sales and services. This necessitates a digital transformation that can be fairly radical, depending on your maturity level. Recently I heard a quote from a CPG (consumer packaged goods) manufacturer with the biggest bakery in North America, and the highest volume croissant producer in the world. They’ve had a revelation about the nature of their business: “We’re a technology company that bakes!”

So how do you become a customer-centric tech company that happens to manufacture products?

In short, by focusing on the end-customer in everything you do:

True customer-centric strategy requires your entire organization

Look at your current strategy. With the changing landscape, manufacturers are looking to create new top-line revenue growth that extends beyond traditional models. Creating customer-centric journeys means nothing if not embraced by the entire organization. These journeys require buy-in from top-to-bottom and bottom-to-up. Building new ways to engage customers—and exceed their expectations—is not a task of one business function, but of the whole organization. Investing in technology likewise won’t be effective if done in siloes.

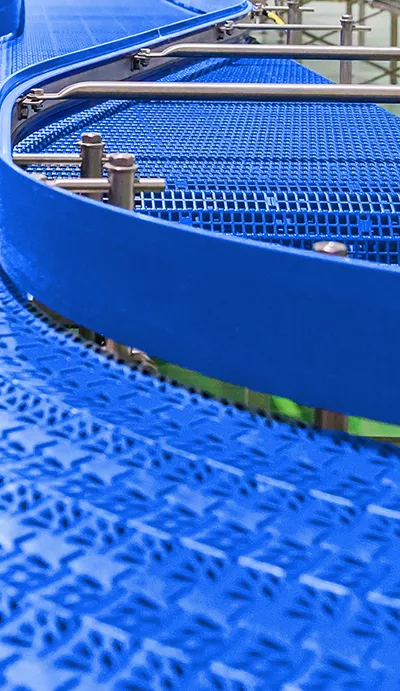

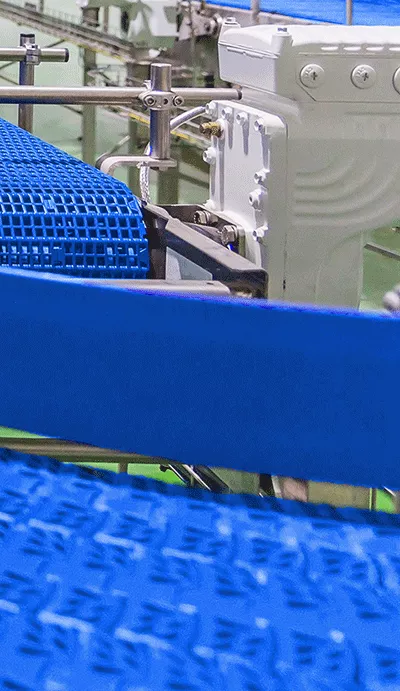

Digitally powered factories

Are your factories really digital? You can answer “yes” if you’re able to gain insights and optimize operational effectiveness via data—continuously and in an interconnected value chain—and if you’re using a pragmatic, technology-agnostic, business-oriented approach to improve your manufacturing structure—by focusing on capabilities with the greatest impact on tangible business value. Use cases in truly digital factories include digital twin (a collection of digital data representing a physical object), networks of sensors for predictive maintenance of machines and robots, cloud robotics, and remote quality inspection.

Unblocking the power of data-driven manufacturing

Data is everywhere, from machines to the supply chain. According to BCG's recent study with heavy manufacturers, nearly three quarters (72%) of manufacturing executives consider data and advanced analytics to be more important now than they were three years ago. There’s a big shift happening, especially with the combination of data from different sources for a more complete picture. For manufacturers, data sources include physical assets, factories, sales, services, and supply chains—all being used to create a more data-driven culture across organizations and to unlock the collective gold mine buried in different systems. There is a use case around operations improvements, enhancing customer experience, and environmental and social impact.

Customer 360

Many manufacturers are consolidating their sales and service interactions to provide a unified view of inventory—to both their channels and their customers. They’re digitizing what used to be institutional knowledge, moving from paper-and-pencil notes to centralized account management. Some innovative manufacturers are moving up the value chain and developing complex products with more favorable margins, while simultaneously offering new services built around these products to provide “products-as-a-service” (PaaS).

Supply chain optimization

Traditionally, supply chains are disconnected processes with no consolidation of data across the whole end-to-end supply chain. But the biggest driver for supply chain leaders is to reduce cost and gain efficiency. Spurred on by COVID, manufacturers and suppliers are taking the opportunity to build more resilient supply chain networks, as time consuming as it can be. Many manufacturers are also breaking down siloes—opening up their ecosystem to their suppliers, and leveraging technologies like cloud, IoT, ML/AI, and blockchain to move from a reactive to a more proactive mode of operations.

Change management and culture transformation

One of the biggest topics for manufacturing CEOs right now is driving change management internally to embrace the new way of doing things. Embracing a change in the manufacturing business and launching new PaaS offerings requires a significant change in your organization’s culture. Excellent proof-of-concept endeavors sometimes don’t move into production due to resistance to change. Agile change management and culture transformation is required across the organization to fully embrace a data-powered, customer-centric model.

Taking that first step

We know this is all a lot easier to say than to do! The journey to build a customer-centric organization takes place one step at a time. We have a lot of practical experience working with other manufacturers and are here to help. Let’s talk about how our partners allow us to do more together.